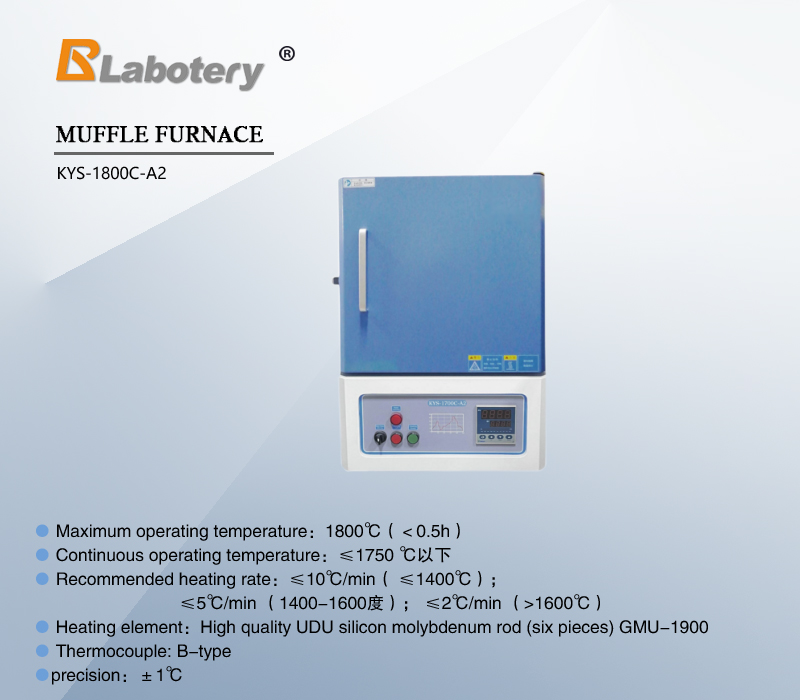

KYS-1800C-A2- Muffle Furnace

A high-temperature muffle furnace, using silicon molybdenum rods as heating elements, adopting a double-layer shell structure and PID program temperature control, B-type thermocouple, and high-purity alumina fiber material for the furnace. The maximum temperature can reach 1800 ℃, and the continuous working temperature is 1750 ℃ with a temperature control accuracy of ± 1 ℃. The furnace has the advantages of uniform temperature field, low surface temperature, and energy saving.

Furnace structure

The surface of the inner furnace is coated with high-temperature alumina imported from the United States, which can improve the reflectivity and heating efficiency of the equipment, while also extending the service life of the instrument; Equipped with overheating and disconnection protection;

Adopting a double-layer shell structure, with an air-cooled circulation system between the double-layer furnace shells;

Heating on both sides of the furnace, with fast heating rate and uniform temperature field;

The furnace door is equipped with a safety limit switch, and a protective latch is installed on the furnace door to prevent accidental opening and explosion;

Main features:

The furnace material adopts high-purity alumina fiber, which can greatly reduce energy loss; Coating the furnace surface with high-temperature alumina imported from the United States can improve heating efficiency and service life; Equipped with overheating and disconnection protection; Using 1900 grade high-quality silicon molybdenum rods, the highest temperature can reach 1800 ℃.

Certification standards and core components:

The core components include ABB, OMEGA, Dongming, etc;

Using ABB electrical components, UL certified materials, and quality certification standards for export to the European Union;

After sales warranty:

Warranty period of one year, lifetime maintenance; 24-hour online service

Special statement: Consumables such as heating elements, quartz tubes, crucibles, etc. are not included;

Damage caused by the use of corrosive and acidic gases is not covered by the warranty;

Precautions for use:

Please put in the cushion block and door stopper before use, otherwise it will damage the furnace and door;

When individual heating elements are damaged for some reason and need to be replaced, it is necessary to select components with suitable resistance values based on the increase in resistance values of other components at that time, and not replace them with new components at will. If there is significant damage to the components or if the resistance value increases too much to reach the required furnace temperature, it is best to replace all components with new ones;

To maintain the service life of the furnace components, we recommend a heating rate not exceeding 10 ° C/min. The cooling rate shall not exceed 10 ° C/min;

It is prohibited to sinter flammable, explosive, toxic, and corrosive substances in the furnace. If the customer's process requires the use of flammable, explosive, toxic, and corrosive substances, please take relevant protective and explosion-proof measures on your own. Our company is not responsible for any issues caused by the use of flammable, explosive, toxic, and corrosive substances.

| model | KYS-1800C-A2 |

| maximum temperature | 1800℃(<0.5 h) |

| Continuous operating temperature | 1750 ℃以下 |

| Recommended heating rate | ≤10℃/min( ≤1400℃); |

| heating zone | 205mm×205mm×205mm; |

| Heating zone space | 8.6L |

| thermocouple | B-type |

| rated power | 5.3 KW |

| rated voltage | 220V 50/60Hz |

| External dimensions | 555mm×665mm×805mm |

| heating element | High quality UDU silicon molybdenum rod (six pieces) GMU-1900 |

| temperature control | Includes a YD858 temperature controller; |